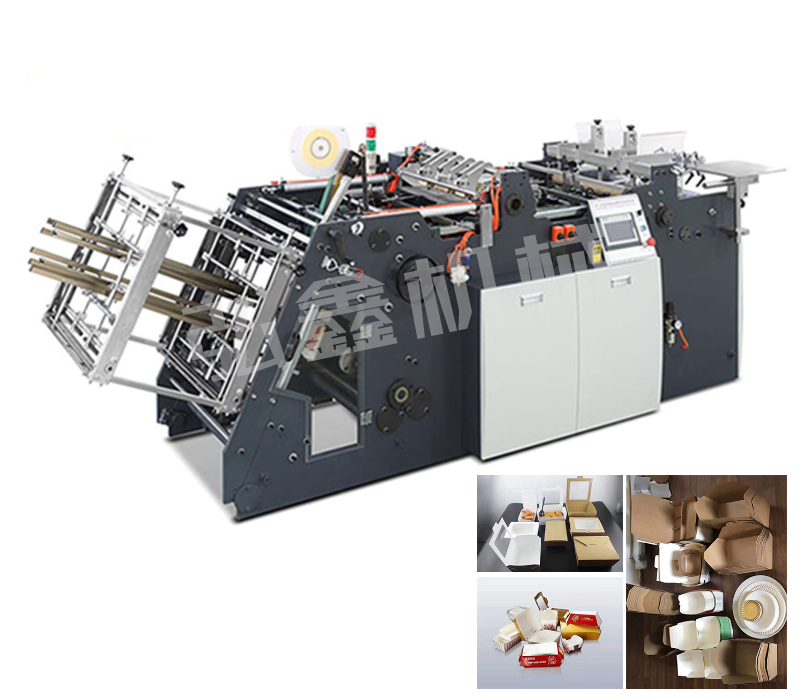

8 Year Exporter Making Paper Cups Machine - FTPCM-Y Paper Cup (Bowl) Jacket Forming Machine – Hongxin

8 Year Exporter Making Paper Cups Machine - FTPCM-Y Paper Cup (Bowl) Jacket Forming Machine – Hongxin Detail:

Technical parameter:

| Product model | FTPCM-Y |

| Paper cup specifications | 6-20 ounce paper cups, 20-50 ounce paper bowls |

| Paper cup material | coated paper, gray-bottomed white paper (200-350g/m2) |

| Product power supply | 380V 50Hz/380V 50Hz |

| Total power rate | 4Kw |

| Product weight | 1100KG |

| Fixed production rate | 40-50 pcs/min |

| Dimensions (length x width x height) | 2250*1250*1750mm |

AFTER-SALES SERVICE:

1. This instruction manual will be sent with the machine to guide the work of the installation process, adjust the machine, produce, avoid or solve problems faced by the buyer.

2. Trial run and training of the machine:

A.we will make a complete adjustment to the machine one week before delivery to ensure that the machine achieves the desired performance.

B.we provide the buyer with free training in our factory. The training will not stop until the buyer controls the whole course! The travel expenses shall be borne by the buyer (on-site installation instruction, auxiliary debugging, daily maintenance, maintenance personnel training) .

3. We provide one-year free supplies accessories, freight borne by the buyer, free warranty for one year.

Our Commitment:

1. We guarantee any defects in design and workmanship within one year from the date of shipment;

2. In normal production, the qualified rate is higher than 99% ;

3. An operator can handle multiple machines at the same time.

Product detail pictures:

Related Product Guide:

In order to fulfill the responsibility of ensuring the quality and safety of the products and services provided by the organization, and to guide the organization to assume the main responsibility of quality and safety, the company attaches great importance to the construction of quality management system, and strictly controls the quality of products, and to meet the standards of indicators at the same time, the establishment of a sound quality management system. In order to ensure that the internal operation in line with ethical requirements, the company developed a measure of ethical behavior indicators and methods. The following table: Quality is formed in the whole process of product life cycle, including the whole process of research and design, trial-manufacture, test, manufacture, distribution, service and use. Therefore, it is necessary to control all kinds of factors that affect product quality in the whole process of product life cycle, to enable the company to continue to provide in line with quality standards and customer satisfaction products, establish a superior quality corporate image, wholeheartedly for customer service. 8 Year Exporter Making Paper Cups Machine - FTPCM-Y Paper Cup (Bowl) Jacket Forming Machine – Hongxin , The product will supply to all over the world, such as: Danish, Miami, Cyprus, Hongxin Machinery Co. , Ltd. is a professional manufacturer of Paper Cup machine, Paper Bowl machine. The Paper Cup crimping machine is a new type of machine developed by our company. It is a supporting equipment for the production line of Paper Cup and Paper Bowl, the utility model is beneficial to the sticking of the aluminum foil cover, such as Yoghurt Cup, enhancing the sealing performance and the fresh-keeping function.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.