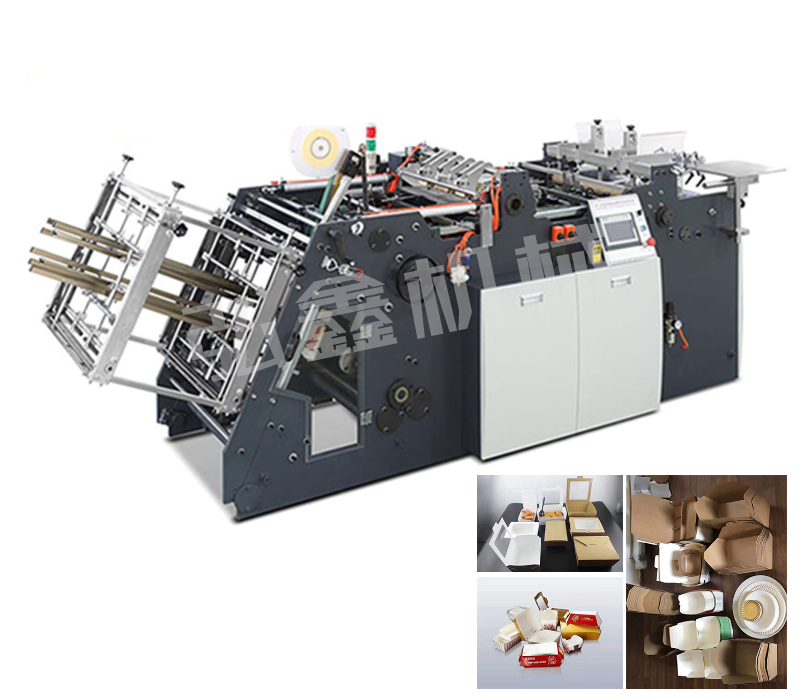

Special Design for Burger Box Making Machine - FTPCM Special cone coat machine – Hongxin

Special Design for Burger Box Making Machine - FTPCM Special cone coat machine – Hongxin Detail:

Technical parameter:

| Material | Pearl Cotton |

| Glue | hot melt glue |

| Power rate | 1.5KW |

| Air source | 0.4 square meters |

| Production speed | 30-40 pcs/min |

AFTER-SALES SERVICE:

1. This instruction manual will be sent with the machine to guide the work of the installation process, adjust the machine, produce, avoid or solve problems faced by the buyer.

2. Trial run and training of the machine:

A.we will make a complete adjustment to the machine one week before delivery to ensure that the machine achieves the desired performance.

B.we provide the buyer with free training in our factory. The training will not stop until the buyer controls the whole course! The travel expenses shall be borne by the buyer (on-site installation instruction, auxiliary debugging, daily maintenance, maintenance personnel training).

3. We provide one-year free supplies accessories, freight borne by the buyer, free warranty for one year.

Our Commitment:

1. We guarantee any defects in design and workmanship within one year from the date of shipment;

2. In normal production, the qualified rate is higher than 99% ;

3. The mechanical transmission part is guaranteed for 5 years, and the whole machine can be repaired free of charge within one year if there is any problem (not including any damage caused by abuse, improper operation, neglect and other reasons beyond our responsibility) .

Product detail pictures:

Related Product Guide:

At present, the company has developed a series of quality control measures, covering from product design, raw material procurement, product manufacturing, product inspection, performance testing, packaging and storage to customer service and other links, at the same time, the company to meet customer requirements as the standard, by the specialized departments responsible for the continuous improvement of product quality work. Special Design for Burger Box Making Machine - FTPCM Special cone coat machine – Hongxin , The product will supply to all over the world, such as: South Korea, Philippines, Finland, Paper Cup production companies to create food-grade production environment, eliminate production link pollution. Production area: changing room, ultraviolet disinfection room, production area, laboratory, Molding Workshop, etc. . In accordance with the National Food Purification Project dust-free workshop standards improvement, particle concentrations or microbial concentrations in the production area were measured 24 hours a day. Paper Cup production company in the design needs to launch a new standard in line with the national design template, constantly recommended to new and old customers. In the pre-production design link, constantly guide customers to accept the New Paper Cup design style, actively to the new national standard close. Paper Cup manufacturing companies to ensure that the use of fluorescent agents, whitening agents, recycled pulp and other inferior paper, eliminate the inherent health of the cup from the source. According to the regulations, Paper Cup production company to each batch of paper for strict factory registration. There are many kinds of machines, we have to choose the right products according to their own requirements, not too high price is not too low, understand the performance of the machine is also very important, I believe that the future development will be better!

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!