HXZS-90 Middle Speed Paper Cup Making Machine

Technical parameter:

| Technical parameter: | |

|

Paper cup specifications |

2-16oz |

|

Production speed |

80-100pcs/min |

|

Machine net weight |

2600kg |

|

Power supply |

380V/50HZ |

|

Air consumption |

0.4m/min |

|

Power |

8KW |

|

Appearance size |

L2400mm*W1250mm*H1700mm |

|

Paper specifications |

150-300gsm |

|

Paper cup bonding method |

Ultrasonic bonding |

|

Paper type |

Single PE/double PE/PLA |

|

We can customize the machine and mould according to customer's requirements |

|

Description

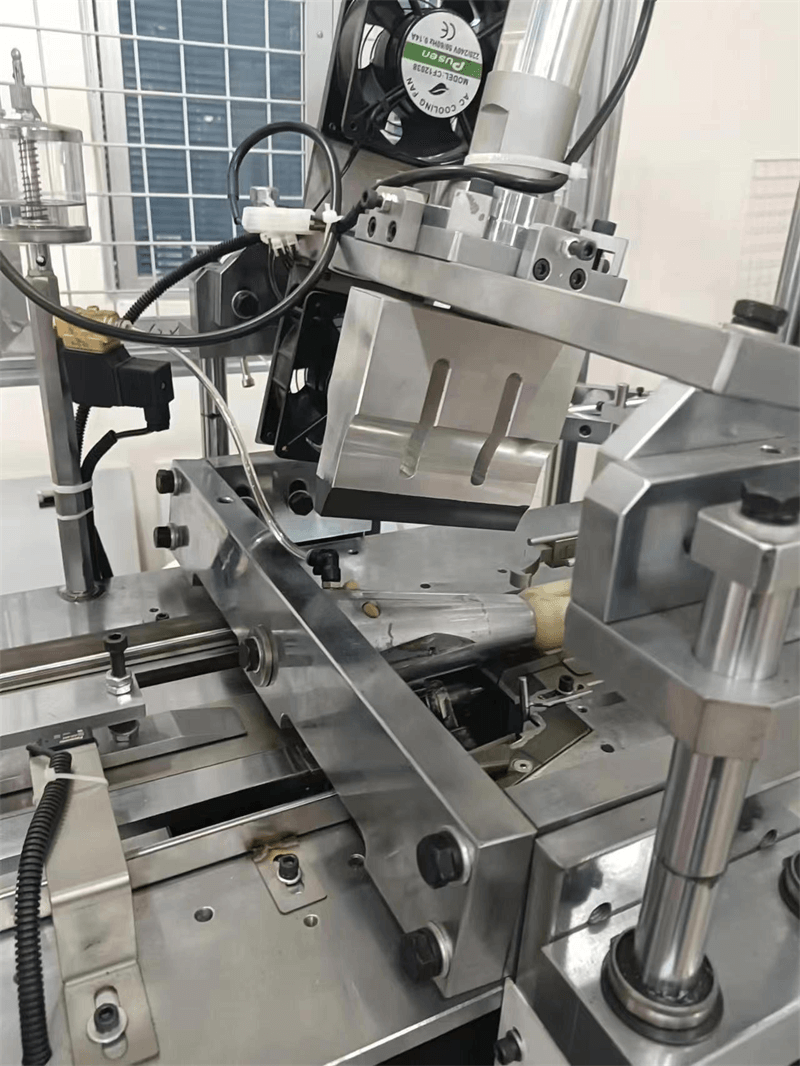

HXZS-90 Medium Speed Paper cup making machine is a paper cup forming machine completed by a single turntable. It adopts an open intermittent indexing mechanism, gear transmission, synchronous belt drive, vertical axis structure, and a separate lifting structure for the curling, which reduces the stroke of the main functional mechanism.

It has reasonable distribution of various functional assemblies. The whole machine adopts the method of regular quantity grease lubrication in time, which reduces the wearing of machine parts. Whole cup making process is controlled by PLC, with photoelectric sensor monitoring. The step motor control paper feeding(have paper then feeding, no paper, then no feeding).

In order to improve the performance of the equipment, achieve fast and smooth operation, realize automatic shutdown of the fault, great.By simplifying the cup making process, feeding, adhesive, cupping, bottoming, heating, bottoming, knurling, curling, unloading, inspection, and automatic counting. Our machine is best choices for making paper cups.reduce the labor intensity of the workers, and improve the safety and stability of the equipment.

1.Ultrasonic sealing for cup body, both okay for single or double PE coated paper.

2.It is formed by one turntable for paper cup forming, which reduces the stroke of the main functional machanism and rationally distributes the various functional assemblies.

Full-automatic lubricating system is applied, thus leading to a long lifespan, with less human maintaince. Also the oil can be recycle used.

3.Photoelectricity sensor to track every step.

4.a.Auto alarm when paper fan go short.

b.Auto stop when multi paper fans delivery.

c.Auto alarm when any fault on the machine.

d.Gear transimission is more stable than chain transmission,and with high precision