Full Automatic Paper Cup Shaping Machine - Factory, Suppliers, Manufacturers from China

For more than 10 years, Hongxin has been actively fulfilling and assuming the responsibilities and obligations of corporate citizenship while creating extraordinary business performance, and actively rewarding the society in a planned way. New Discovery has been committed to charity funding, in 2022 to participate in theMicro-wish campaign, for 2 families of poor children present. At the same time, Hongxin worked closely with engineers from South China University of Technology, Guangdong University of Technology and other institutions to set up scholarships to encourage hardworking students. Full Automatic Paper Cup Shaping Machine, Automatic Cup Making Machine , Disposable Paper Cups Manufacturing Machinery , Fully Automatic Paper Bowl Machine,Automatic Paper Bowl Machinery . The history of paper cups has gone through four stages: Cone/fold paper cups, cone paper cups the first paper cups were cone-shaped, hand-made, glued together, easier to separate, must be used as soon as possible. Later, folding cups were added to the side walls to increase the strength of the side walls and the durability of the cup, but it is more difficult to print patterns on these folding surfaces, and the effect is not very good. Waxed Paper Cup in 1932, the first two waxed paper cup came out, its smooth surface can be printed on a variety of exquisite patterns, improve the promotion effect. On the one hand, the wax coating on the paper cup can avoid the direct contact between the drink and the paper material, and can protect the adhesive and enhance the durability of the paper cup; on the other hand, it also increases the thickness of the side wall, which greatly improves the strength of the Paper Cup, thus, the paper consumption necessary for manufacturing stronger paper cups is reduced, and the production cost is reduced. The product will supply to all over the world, such as Europe, America, Australia,Egypt, Luxembourg,Manila, Jamaica.Paper Cup production companies to create food-grade production environment, eliminate production link pollution. Production area: changing room, ultraviolet disinfection room, production area, laboratory, Molding Workshop, etc. . In accordance with the National Food Purification Project dust-free workshop standards improvement, particle concentrations or microbial concentrations in the production area were measured 24 hours a day. Paper Cup production company in the design needs to launch a new standard in line with the national design template, constantly recommended to new and old customers. In the pre-production design link, constantly guide customers to accept the New Paper Cup design style, actively to the new national standard close. Paper Cup manufacturing companies to ensure that the use of fluorescent agents, whitening agents, recycled pulp and other inferior paper, eliminate the inherent health of the cup from the source. According to the regulations, Paper Cup production company to each batch of paper for strict factory registration. There are many kinds of machines, we have to choose the right products according to their own requirements, not too high price is not too low, understand the performance of the machine is also very important, I believe that the future development will be better!

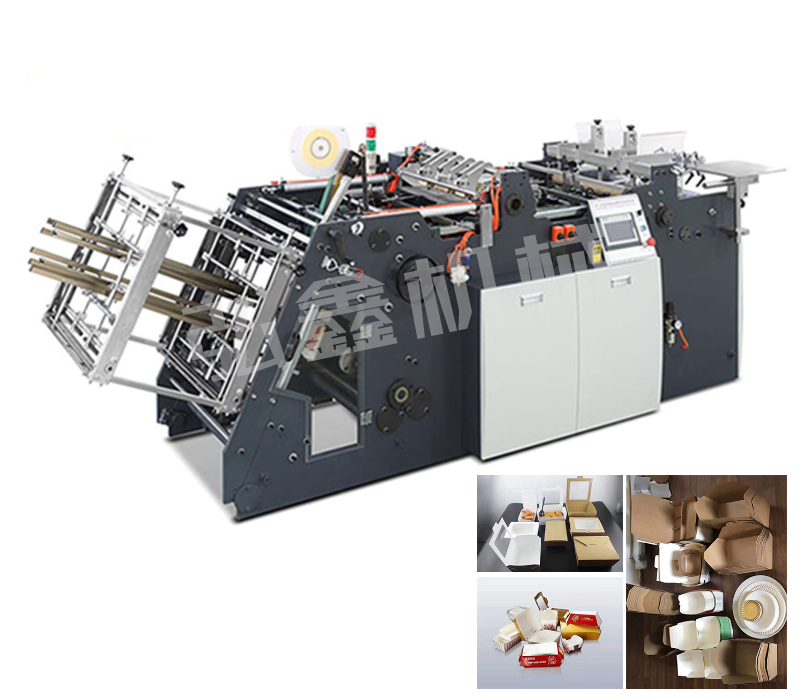

Related Products