Factory Supply Paper Cup Forming Machinery - Automatic PLC Single Tray Paper Cup Machine – Hongxin

Factory Supply Paper Cup Forming Machinery - Automatic PLC Single Tray Paper Cup Machine – Hongxin Detail:

Product Video

Technical parameter:

|

Paper cup specifications |

2-16oz |

|

Production speed |

80-100pcs/min |

|

Machine net weight |

2600kg |

|

Power supply |

380V/50HZ |

|

Air consumption |

0.4m/min |

|

Power |

8KW |

|

Appearance size |

L2400mm*W1250mm*H1700mm |

|

Paper specifications |

150-300gsm |

|

Paper cup bonding method |

Ultrasonic bonding |

|

Paper type |

Single PE/double PE/PLA |

|

We can customize the machine and mould according to customer’s requirements |

|

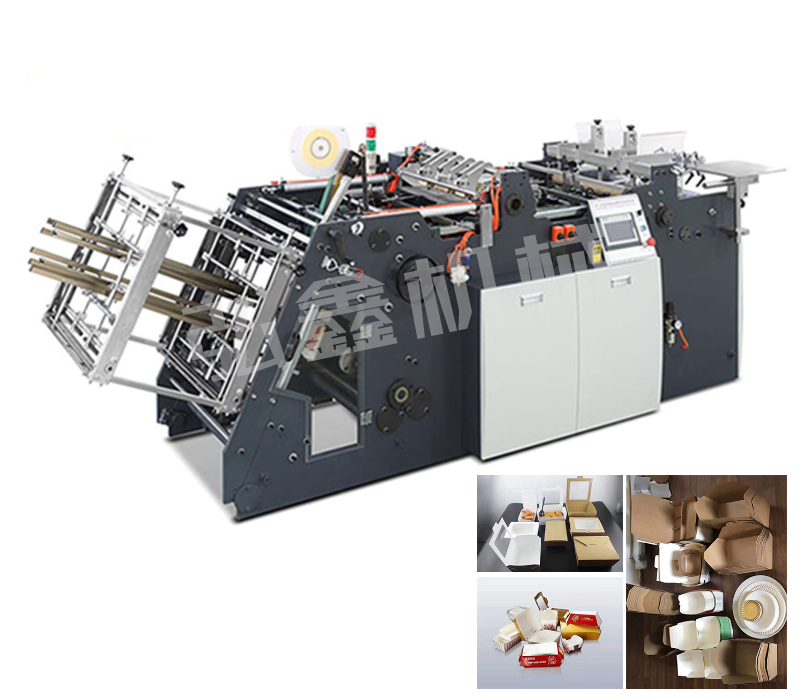

FTPCM-PLC single tray paper cup machine is a brand new model developed by our company based on years of paper cup machine manufacturing experience combined with medium-speed paper cup machine. It is an advanced domestic paper cup forming equipment. The frame is welded with rectangular pipe and channel steel, with high strength and small deformation. The whole machine adopts the method of spraying and lubricating to reduce the wear of machine parts. The bottom of the cup is formed by a stretch die, and the bottom of the cup has a good forming effect, thereby reducing the chance of water leakage. The cup-making process is PLC controlled, photoelectric eye tracking failure shutdown monitoring system, servo-controlled bottom feeding, bottom feeding if there is a cup tube, and no bottom feeding if there is no cup tube. Robotic design, equipped with safety protection devices, beautiful and generous, is an ideal replacement product for the original three-turntable model.

FUNCTION:

1. We guarantee any defects in design and workmanship within one year from the date of shipment.

2. Production per shift (8 hours) is about 38,400 cups, or about 3.24 million cups per month (20 hours a day given the protection of the machine).

3. In normal production, the qualified rate is higher than 99% ;

4. An operator can handle multiple machines at the same time.

5. The mechanical transmission part is guaranteed for 5 years, and the whole machine can be repaired free of charge within one year if there is any problem (not including any damage caused by abuse, improper operation, neglect and other reasons beyond our responsibility).

FUNCTION:

Automatic Rejection function when boot. Paper Conveyer Belt is the supporting equipment of Paper Cup forming machine. It can reduce the frequency of adding paper per unit time and achieve the goal of saving labor cost.

Product detail pictures:

Related Product Guide:

First of all, the paper cup relative to the words will look some grade, and above if you want to carve patterns, the relative cost will be lower. Like the general important occasion, will use paper cups to entertain guests. Plastic Cups, however, are more cumbersome to handle and require more work and time. And paper cups are not polluting the environment. This kind of cup can actually be completely degraded after use, while plastic can cause white pollution, both from the looks of it and the soil itself are contaminated. At the moment, paper cups are more expensive than plastic ones, but they're healthier for drinking from, and plastic can be more or less harmful at high temperatures. So for their own health, of course, to abandon the plastic cup to use paper cups to drink water. Of course, another feature of paper cups is that their thermal conductivity is not very good. In winter, if you drink a cup of hot water from a plastic cup, holding it in your hand will be very hot, but the paper cup is different, this time the hand can just warm but not hot. So to sum up, whether it is from the environment, health, or convenience, paper cups will have more advantages, is the best choice. Factory Supply Paper Cup Forming Machinery - Automatic PLC Single Tray Paper Cup Machine – Hongxin , The product will supply to all over the world, such as: Jersey, Zambia, Gambia, Paper Bowl machine in the application of the industry

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!