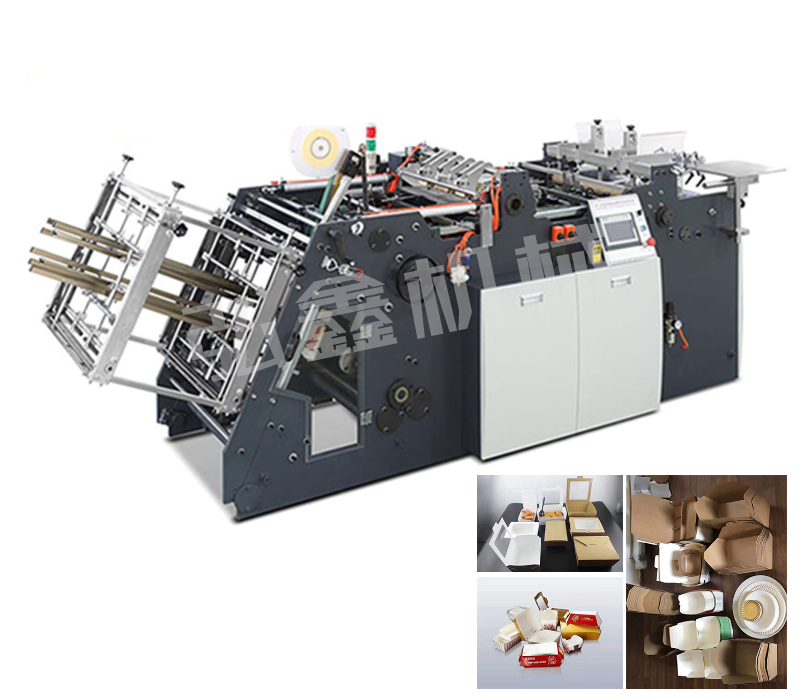

18 Years Factory Paper Cup Making Machinery - FTPM-D Fully automatic paper doyleys machine – Hongxin

18 Years Factory Paper Cup Making Machinery - FTPM-D Fully automatic paper doyleys machine – Hongxin Detail:

Technical parameter:

| The width of the decorative paper is less than | 400mm |

| Flower paper length is less than | 600mm |

| Paper mantissa less than or equal to | 4 layers |

| The diameter of the paper roll is less than | φ 1000mm |

| Paper category | 50-60gin bleached paper |

| Production capacity | 188pcs/min |

| Steel mold speed | 47r/min |

| Weight | 700kg |

| Dimensions | 2500x1500x1650 |

| Total power of power supply | 380V 50Hz 3.05Kw |

| It is suitable for producing round, square and oval flower shading with a diameter between 420-100mm (that is, between 16.5 inches and 4.5 inches).The power of the whole machine is less than 3KW.The maximum production decal size is 25×16.5 inches long x 16.5 inches wide and 16.5 inches in diameter. | |

AFTER-SALES SERVICE:

1. This instruction manual will be sent with the machine to guide the work of the installation process, adjust the machine, produce, avoid or solve problems faced by the buyer.

2. Trial run and training of the machine:

A.we will make a complete adjustment to the machine one week before delivery to ensure that the machine achieves the desired performance.

B.we provide the buyer with free training in our factory. The training will not stop until the buyer controls the whole course! The travel expenses shall be borne by the buyer (on-site installation instruction, auxiliary debugging, daily maintenance, maintenance personnel training) .

3. We provide one-year free supplies accessories, freight borne by the buyer, free warranty for one year.

Product detail pictures:

Related Product Guide:

HONGXIN do a good job in environmental protection. From the purchase of raw materials to the production process, the whole process of hazardous substances control. According to the performance of the management system and the annual management review meeting, set the continuous improvement goals and management programs, and implement them to the responsible departments, which are followed up by the General Affairs Department on a quarterly basis, to achieve the environment, energy resources, security management performance of the continuous improvement. In safety production, the company has always followed the“Focus on safety, prevention-oriented” work policy, starting from training staff safety awareness, carrying out three-level safety education, according to the safety characteristics of different positions, take safety precautions such as on-the-job safety training, provision of labor protection supplies, payment of old-age pension and industrial injury insurance for all employees, etc. to ensure that all employees have the safety knowledge and skills required by the job, to ensure the personal safety of employees. Every year, the company organizes a free medical check-up for the employees who are in contact with the occupational hazards. If the diseases are found in the check-up, they should be reminded and arranged to see a doctor . 18 Years Factory Paper Cup Making Machinery - FTPM-D Fully automatic paper doyleys machine – Hongxin , The product will supply to all over the world, such as: Tajikistan, Costa rica, Juventus, The paper bowl machine is a general equipment used for making disposable paper bowls. There are paper bowl machines for making disposable paper bowls and cup-making machines for making disposable plastic bowls, specific paper bowl manufacturing equipment selection can be based on the manufacturing process to determine. Paper Bowl machines have only emerged in the last few years, especially in some banquets where they are most widely used. There are also some related equipment such as spoon machines, Paper Cup machines, and so on. These equipment work in a similar way, using paper as the material, some things use plastics as raw materials for manufacturing. Paper Bowl machine produced by the paper bowl requirements are very high, the need for paper bowl manufacturing materials absolute health and safety, and moisture-proof, moisture-proof, heat insulation, heat preservation. Paper Bowl machine to make different shapes of paper bowl need to change the mold. Some paper bowls, paper cups, plastic cups and other products bought in the market are all made using paper bowl machines. Because of the wide use of people and the large market, the competition in the paper bowl machine manufacturing industry is extremely fierce, when we buy paper bowls, we need to ensure the hygiene of the products!

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.

Write your message here and send it to us